Cable Selection Guide (Malaysia): PVC vs XLPE, Copper vs Aluminium, Armoured vs Non-Armoured

Choosing the right electrical cable isn’t just about price. In Malaysia, cable selection affects safety, heat performance, lifespan, compliance with Suruhanjaya Tenaga (ST) and long-term maintenance cost.

In this guide, See Kwong breaks down the real-world differences between the most common cable choices used in Malaysian homes, shops, and factories — without overcomplicating things.

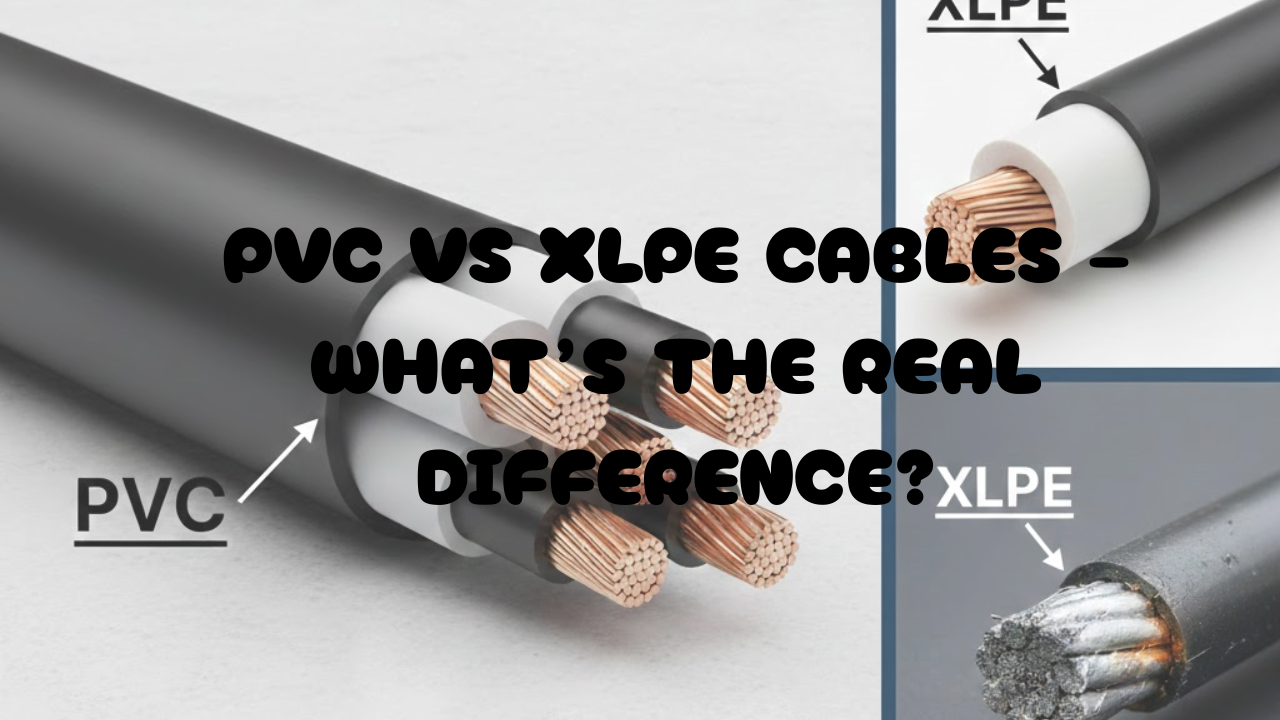

1. PVC vs XLPE Cables – What’s the Real Difference?

This is usually the first decision engineers, contractors, and electricians make.

PVC (Polyvinyl Chloride) Cables

Common in: Houses, small shops, light commercial buildings

Pros:

Lower cost 💰

Easy to install

Widely available in Malaysia

Suitable for normal indoor wiring

Cons:

Lower heat resistance

Shorter lifespan under high load

Not ideal for hot environments

Typical Rating:

Max operating temperature: 70°C

Best used when:

Lighting circuits

Socket outlets

Short cable runs

Residential DB wiring

👉 Most Malaysian homes use PVC — and that’s perfectly fine.

XLPE (Cross-Linked Polyethylene) Cables

Common in: Factories, high-rise buildings, main feeders

Pros:

Handles higher temperature 🔥

Higher current-carrying capacity

Better insulation strength

Longer service life

Cons:

Higher upfront cost

Slightly stiffer to install

Typical Rating:

Max operating temperature: 90°C

Best used when:

Main incoming cables

High-load machinery

Long-distance runs

Panels with higher ambient temperature

👉 If heat, load, or future expansion is a concern — XLPE is worth it.

Quick PVC vs XLPE Summary

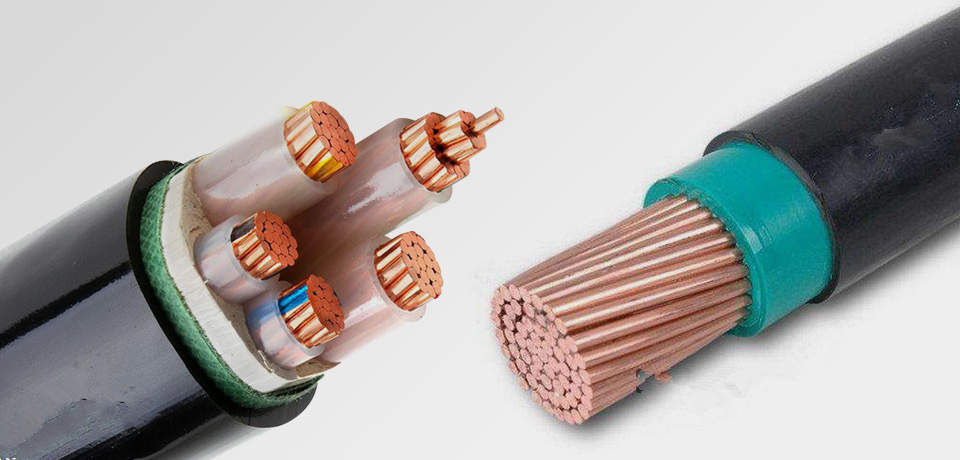

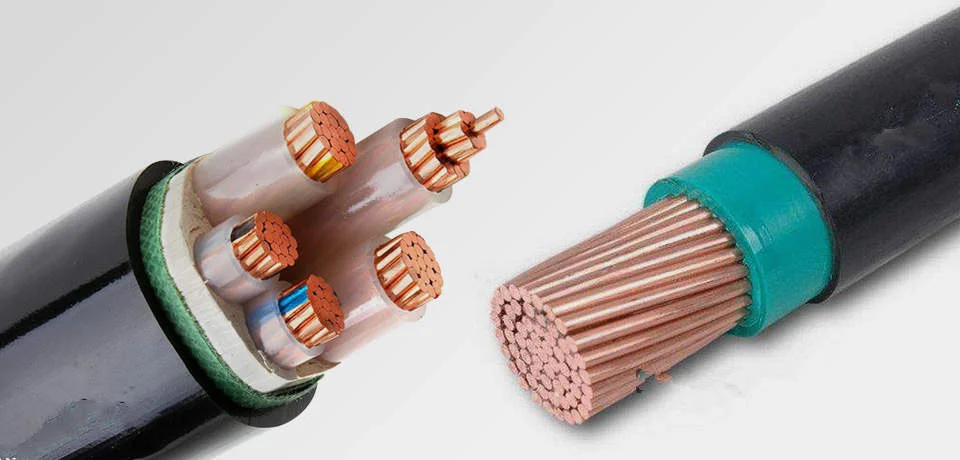

2. Copper vs Aluminium Cables – Which Should You Choose?

This choice affects performance, termination quality, and long-term reliability.

Copper Cables

Common in: Almost all Malaysian installations

Pros:

Excellent conductivity ⚡

Smaller cable size for same current

Stronger, less prone to breakage

Easier and safer termination

Cons:

Higher material cost

Best used when:

Internal wiring

Control panels

DBs and switchboards

Where reliability matters most

👉 Copper is still the gold standard in Malaysia.

Aluminium Cables

Common in: Long-distance feeders, utility connections

Pros:

Much cheaper per meter

Lightweight

Cost-effective for large sizes

Cons:

Larger size needed for same current

Requires proper lugs & jointing

Higher risk if workmanship is poor

Best used when:

Long cable runs

Budget-sensitive projects

Proper termination tools are available

👉 Aluminium works — but only with correct design and installation.

Copper vs Aluminium Summary

3. Armoured vs Non-Armoured Cables – Do You Really Need Armour?

This decision is about mechanical protection, not electrical performance.

Non-Armoured Cables

Common in: Conduit, trunking, indoor installations

Pros:

Cheaper

Lighter

Easier to pull and install

Cons:

No mechanical protection

Easily damaged if exposed

Best used when:

Installed in conduit or trunking

Indoor environments

No risk of impact or digging

👉 Perfectly safe when installed properly.

Armoured Cables (SWA / STA)

Common in: Outdoor runs, underground, factories

Pros:

Strong mechanical protection 💪

Suitable for direct burial

Extra safety against impact

Cons:

Higher cost

Heavier and harder to install

Requires proper earthing

Best used when:

Outdoor cable routes

Underground installations

Exposed industrial areas

Risk of physical damage

👉 If the cable is exposed — armour is not optional.

Armoured vs Non-Armoured Summary

4. How Malaysians Usually Get It Right (Real-World Tip)

For most projects in Malaysia:

Homes:

PVC + Copper + Non-ArmouredShops & Offices:

PVC or XLPE + Copper + Non-Armoured (in trunking)Factories & Main Feeders:

XLPE + Copper or Aluminium + Armoured

There is no “one cable fits all” — only correct selection for the appli

5. Final Advice from See Kwong

Cable selection isn’t about buying the most expensive cable.

It’s about choosing the right cable for load, environment, and future use — safely and compliantly.

At See Kwong, we help contractors, electricians, and engineers select:

Correct cable type

Proper sizing

ST-compliant solutions